If you’re looking for an efficient and eco-friendly solution for machine cleaning and painting, consider dry ice blasting from Callaway Industrial. Our advanced dry ice blasting technology uses high-pressure air and tiny dry ice pellets to effectively remove dirt, grime, and even tough industrial coatings without damaging the underlying surface. This process is non-abrasive, non-conductive, and non-toxic, making it a safe and environmentally friendly choice for your facility maintenance needs. Contact us today to learn more about our dry ice blasting services and how we can help keep your machines running smoothly.

Dry Ice Blasting Services for Efficient and Eco-Friendly Machine Cleaning and Painting

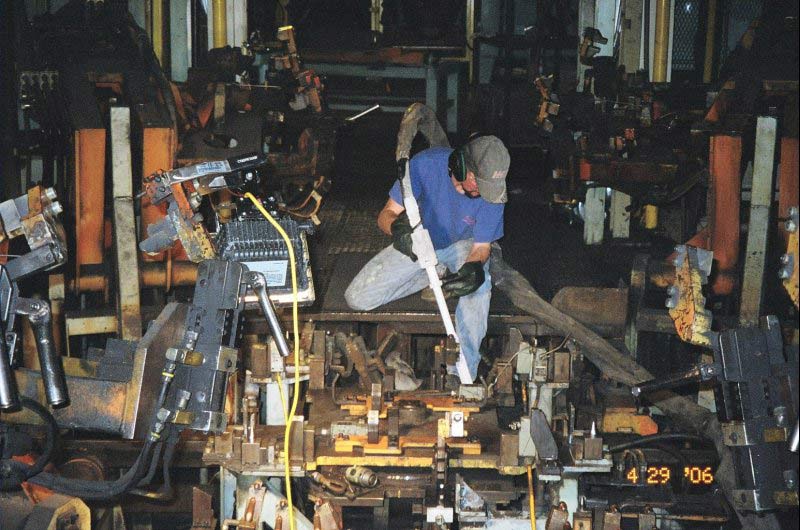

Callaway Industrial offers dry ice blasting services for commercial and industrial applications that provide an environmentally safe solution for machine cleaning and painting. Our advanced technology uses high-pressure air and tiny dry ice pellets to effectively remove dirt, grime, and even tough industrial coatings without damaging the underlying surface.

Dry ice blasting is a form of heavy abrasive cleaning for removing contaminants from mechanical and industrial machines, parts, and more. It is non-abrasive, non-conductive, and non-toxic, making it a safe and eco-friendly choice for facility maintenance needs. Compared to other blasting or cleaning methods such as abrasive blasting or plastic bead blasting, dry ice blasting does not require cleaning up of a blasting medium and leaves no chemical residues which could potentially harm equipment. Dry ice blasting is also far more effective and faster than cleaning by hand.

Efficient and Eco-Friendly Solution

Our dry ice cleaning service entails using CO2 at minus 109.3° in the form of small, rice size pellets of dry ice shooting them out of a jet nozzle with compressed air. The frigid temperature of the dry ice against the material to be removed causes it to shrink and lose adhesion from its sub-surface. When some of the dry ice penetrates through the unwanted foreign material to be removed, the dry ice evaporates. The warmer sub-surface causes the dry ice to convert back into carbon dioxide gas. The gas has 800 times greater volume and expands behind the material speeding up its removal.

Paint, oil, grease, asphalt, tar, decals, soot, dirt, ink, resins, barnacles, coolant, mildew, and adhesives are some of the materials removed by this procedure. Only the removed material must be disposed of, as the dry ice sublimes into the atmosphere. This method is superior to abrasive blasting because the dry ice is soft enough not to pit or damage the underlying surface.

Benefits of Dry Ice Blasting

Dry ice blasting offers numerous benefits, including decreased downtime for equipment. Downtime that was once measured in days can now be measured in hours and minutes. This decreases downtime, strengthens productivity, and increases profitability by getting equipment back to work. Dry ice blasting also eliminates equipment damage in two ways.

First, dry ice does not erode or wear away the targeted surface as traditional grit media and even wire brushes do. This means that surface integrity and critical tolerances are preserved, and equipment will not have to be replaced due to surface erosion common with sand, glass beads, and other abrasive media.

Second, with traditional cleaning methods, equipment is often damaged while in transit to or from the dedicated cleaning area. Instead, most equipment and machinery can be cleaned while in place.

Contact Callaway Industrial today to learn more about our dry ice blasting services and how we can help keep your machines running smoothly with a safe and environmentally friendly solution for your facility maintenance needs.

Dry ice blasting is also more efficient then your standard steam and water blasting process for several reasons:

Contact Callaway Industrial to learn more about dry ice blasting services for your business.